Following a severe internal flooding event at a commercial property, Exjet Services were tasked with identifying the cause of the flooding, and producing a viable solution to prevent a future recurrence.

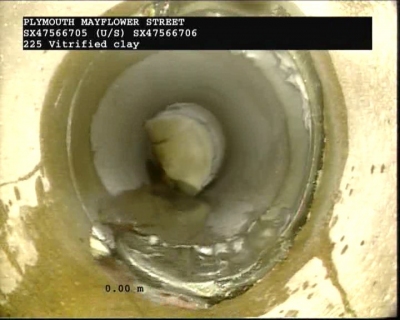

The initial investigation by CCTV surveying, revealed that a structural steel pile had penetrated the sewer at a depth of 6.4m beneath the bus station car park. This had reduced the sewers cross sectional area by 70%.

A number of options were considered in order to alleviate the problem.

The clients initial preference was to divert the sewer away from its original route and reconnect approximately 70m away. This was discounted as excavation would present a high-risk operation due to the excessive depth and proximity to building foundations, significant environmental impact, major cost and disruption to business and the community.

In Situ Pile Pre and Post Cutting

Based on these factors, the client engaged Exjet Services to assess alternative solutions.

Scoping

The outline brief to Exjet required that the pile be removed to an extent where flow could be restored, minimal damage caused to the existing pipe wall and the pipe repaired by means of the installation of a CIPP liner or patch.

From the CCTV footage, it was estimated that the pile was 175-200mm diameter, with (typically) an 8mm wall thickness. The age of the pile meant the reinforced concrete within it would have gained significant strength so the cutting process needed to guarantee removal of the pile, concrete, and any reinforcement steel, whilst ensuring the walls of the broken host sewer pipe were not further damaged.

Managing Director Mr Robin Dowell, evaluated the use of Ultra High-Pressure Water Jetting equipment and then adding an abrasive element (crushed Garnet) to the jet to enhance the cutting ability through both the pile and its core.

Innovation

One of Exjets suppliers was able to adapt a rotary cutting rig to enable the 40,600 psi water jet to be directed and concentrated on a path that followed the internal profile of the host pipe, and was calibrated to ensure a cutting depth of 210mm, penetrating the full thickness of the steel pile and concrete core with the flow rate limited to 20 litres per minute preventing further damage to the host pipe. In addition this solution is also heat and spark free.

Delivery

The pile was successfully cut and removed by Exjet over a period of three days allowing completion of the works with a number of PU patch repairs over the pile location, thus restoring the structural integrity of the pipe and allowing free flows to be restored. Works were fully completed and the car park returned to use within 5 days.